CARF Ultra Flash Evo build thread +

#201

Pilots at our field know that my average cruising speed is about 200 mph.. My previous UF (original versions ) had turbine between 166-200…. All in immaculate shape were sold to my friends..

Not sure if the evo would benefit from bigger turbine due to lack of ducting and the thinner (lighter) construction…. Overall I’m very happy with the light setup.. it’s my relaxing (go to) jet..

For exhilaration I fly my Bolt…

David

Not sure if the evo would benefit from bigger turbine due to lack of ducting and the thinner (lighter) construction…. Overall I’m very happy with the light setup.. it’s my relaxing (go to) jet..

For exhilaration I fly my Bolt…

David

#202

Thread Starter

We are mainly flying Evo’s with JetCat P-130’s (actually over 150N) they rock on just fine. Structure is as strong on the Evo as other UF models…

Dave

Dave

#203

Still flies very well with 120N-140N…. But not sure it will handle a 180N…. Like it’s older brother….

David

#204

Thread Starter

Yes, the original fuselage was like a tank…but we changed that layup a long time back.

The Flash has always been a single front peg-originally a glass 10mm one…

Although I don’t condone a 180…it will take it just fine

The Flash has always been a single front peg-originally a glass 10mm one…

Although I don’t condone a 180…it will take it just fine

#206

I'm waiting for my X180 from the first batch X180 from Gaspar.. will drop it in there and hopefully I remove the mounting rail extension so the X180 will bolt on the original rails... and will advise..

Then I will revert back to my Rebel Classic for relaxing flight... that has a X120 in it...

#207

#209

Wel aftre a few weeks away from building the evo ( due to work)

i have mounted the trust tube i now have an overhang of the outer pipe incl tailcone of about 12mm measured from the end of the thrust pipe

it's my fist pipe instal and in the past i have alway's flown with boomerangs and bobcats.

And as i read in previous post's i need to cut somthing of the tailcone or leave it as is

About the pegs in the tailplane and wing

I have fiberglas pegs in them

regards peter

i have mounted the trust tube i now have an overhang of the outer pipe incl tailcone of about 12mm measured from the end of the thrust pipe

it's my fist pipe instal and in the past i have alway's flown with boomerangs and bobcats.

And as i read in previous post's i need to cut somthing of the tailcone or leave it as is

About the pegs in the tailplane and wing

I have fiberglas pegs in them

regards peter

Last edited by jetpower; 12-09-2021 at 11:26 AM.

#211

Join Date: Dec 2002

Location: Kortessem, BELGIUM

Posts: 3,607

Likes: 0

Received 13 Likes

on

11 Posts

On mine I found out the pipe/bell mouth wasn't perfectly symmetric, so I rotated the thrust tube in the fuselage to find the position where it slides aft the furthest.

This gave me an extra couple of millimeters.

Then I properly sanded/dremeled the fibre glass joining tape away in the tailcone ...with care of course.

The the last millimeter or 2 I needed were achieved by sanding the entire inside perimeter of the tailcone where the thrust tube sits.

I basically just sanded the weave out of the fibre glass, and this was enough to get the pipe to slide a little further.

The pipe now fits almost airtight in the tailcone, except for where it is folded and riveted.

This gave me an extra couple of millimeters.

Then I properly sanded/dremeled the fibre glass joining tape away in the tailcone ...with care of course.

The the last millimeter or 2 I needed were achieved by sanding the entire inside perimeter of the tailcone where the thrust tube sits.

I basically just sanded the weave out of the fibre glass, and this was enough to get the pipe to slide a little further.

The pipe now fits almost airtight in the tailcone, except for where it is folded and riveted.

#215

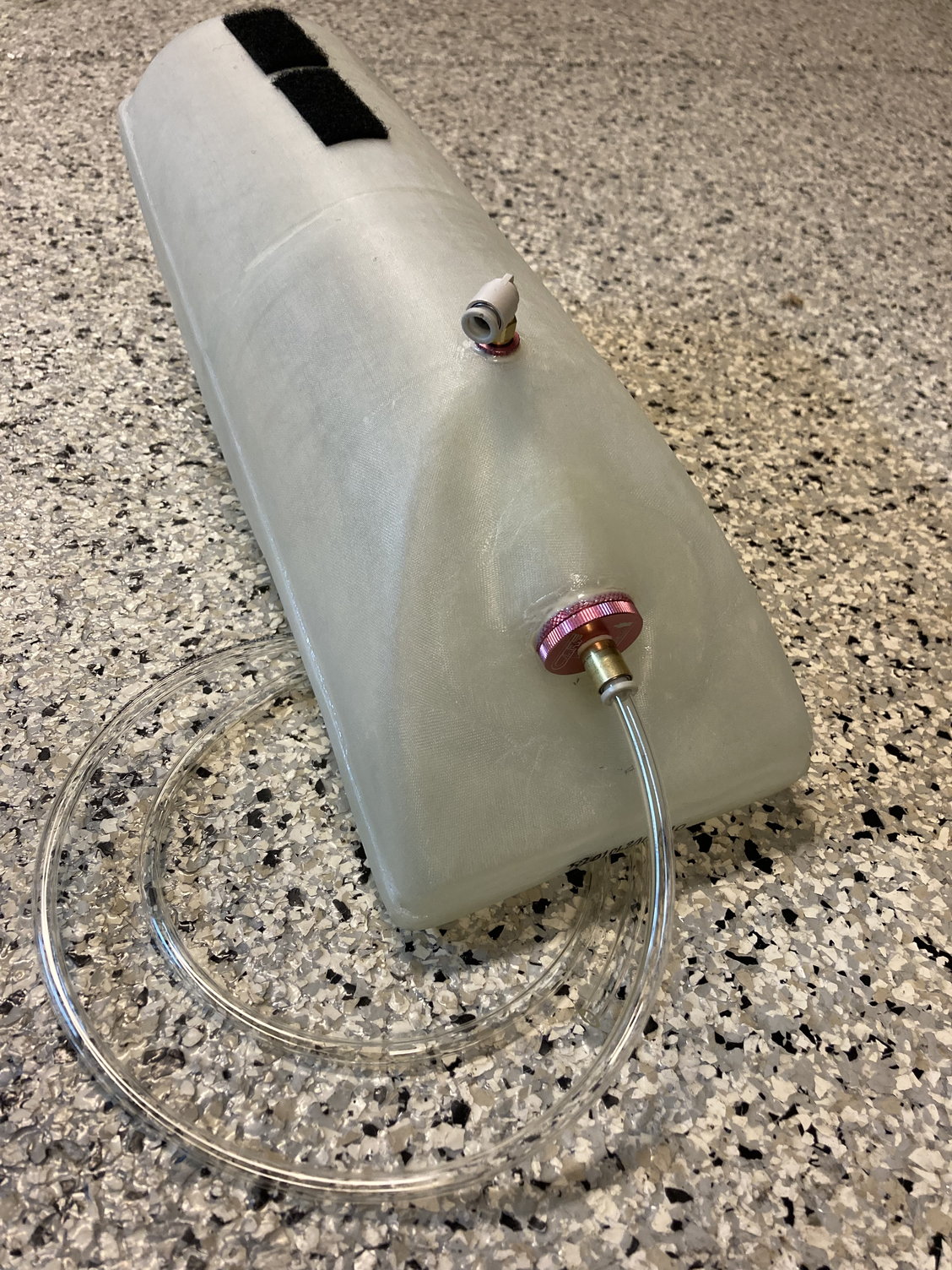

OK guys, builder's block, (I hate when that happens). The fuselage tank that my Evo came with has a vent cut into the top of the tank, the factory was kind enough to pre-install a threaded insert to screw in a 90 degree Festo type fitting. Well, the problem is when I installed the tank, that vent line Festo fitting at the top of the tank hits the top of the fuselage preventing me from sliding the tank all the way into it's final resting place!!! As the tank sits on top of the intakes, there is no room there on the top of the fuselage to accommodate the 90 degree Festo! Any of you guys have a solution?

#216

Thread Starter

This is a CARF tank? I presumed they would stick with the original bung on the UF as there is no space for the top mounted overflow.

Dropping the tank it would be hard on the wing and I still don’t think there is space for a 90 Festo

Dropping the tank it would be hard on the wing and I still don’t think there is space for a 90 Festo

#217

My Feedback: (53)

OK guys, builder's block, (I hate when that happens). The fuselage tank that my Evo came with has a vent cut into the top of the tank, the factory was kind enough to pre-install a threaded insert to screw in a 90 degree Festo type fitting. Well, the problem is when I installed the tank, that vent line Festo fitting at the top of the tank hits the top of the fuselage preventing me from sliding the tank all the way into it's final resting place!!! As the tank sits on top of the intakes, there is no room there on the top of the fuselage to accommodate the 90 degree Festo! Any of you guys have a solution?

#218

Hi Dave,

Yes, it's the tank that came with the kit. You would think that CARF would have thought about that before putting that tank into production. I guess I'll have to cut that fixed piece out of the top of the tank, fiberglass it over, then vent it from the front. I'm not even sure how to make a new vent fitting! grrrrrr!!!!!!!!

#219

#221

My Feedback: (53)

Hi Dave,

Yes, it's the tank that came with the kit. You would think that CARF would have thought about that before putting that tank into production. I guess I'll have to cut that fixed piece out of the top of the tank, fiberglass it over, then vent it from the front. I'm not even sure how to make a new vent fitting! grrrrrr!!!!!!!!

Yes, it's the tank that came with the kit. You would think that CARF would have thought about that before putting that tank into production. I guess I'll have to cut that fixed piece out of the top of the tank, fiberglass it over, then vent it from the front. I'm not even sure how to make a new vent fitting! grrrrrr!!!!!!!!

#222

Ok this is no good, not sure how this got through on the production tank but there is ZERO way this will fit into the fuselage! I’m looking for solutions to this. It would seem to me that I’m gonna have to cut this vent fitting out, glass over this hole, and make a vent fitting at the front of the tank. Any ideas?

#224

Thread Starter

Sorry, yes that’s the best way unless you can wait for CARF to come up with a solution.

Simplest fix would be to get a length of 5/32” brass tube, bend a 90 end tail and Hysol it in the front face with enough out to put the overflow tube on, I guess supporting it is the biggest issue.

Contact your rep in the US, we will see how it’s best to manage this.

Simplest fix would be to get a length of 5/32” brass tube, bend a 90 end tail and Hysol it in the front face with enough out to put the overflow tube on, I guess supporting it is the biggest issue.

Contact your rep in the US, we will see how it’s best to manage this.

#225

Sorry, yes that’s the best way unless you can wait for CARF to come up with a solution.

Simplest fix would be to get a length of 5/32” brass tube, bend a 90 end tail and Hysol it in the front face with enough out to put the overflow tube on, I guess supporting it is the biggest issue.

Contact your rep in the US, we will see how it’s best to manage this.

Simplest fix would be to get a length of 5/32” brass tube, bend a 90 end tail and Hysol it in the front face with enough out to put the overflow tube on, I guess supporting it is the biggest issue.

Contact your rep in the US, we will see how it’s best to manage this.

Thanks Dave, Both Ray and Mike are working on it!