need iformation on old diesels

#26

Join Date: Jul 2005

Location: Upper HuttWellington, NEW ZEALAND

Posts: 1,601

Likes: 0

Received 1 Like

on

1 Post

Enlarge the prop hole by drilling with a bit one size up till it eventually fits?

YES. The important thing is to keep the hole square in both axes while drilling, you do not want to introduce any out of squareness

A toothbrush may not fit inside the cylinder for cleaning.

I never implied it would-you use it for general scrubbing off dirt, grime etc from various surfaces-and you will be able to get it inside the crankcase via the backplate opening. You might recall that I have not suggested that you completely strip the engine-the purpose was the exercise is to get it unseized and in a state where it will run, not strip and clean every part...

Is the a connection between piston and contra-piston?

There is no physical connection between the piston and contra piston. The contra piston is a tightly fitting plug the closes the top of the cylinder and has a small range of vertical movement within the upper cylinder region. It does not move up and down of its own accord while the engine is operating. It may be moved by the operator turning the compression screw during the starting and adjusting for smooth running process. The inside face-that is the one that faces or is 'contra' to the piston forms the combustion chamber-it may be flat, have a concave shallow cone profile or a shallow concave bowl shape depending on the brand of engine-in your case the Hunter has a flat contrapiston face. There is very little clearance between the contra piston face and the piston crown at running settings-a matter of perhaps 0.010 inches or 0.25mm-certainly less clearance than you would find in a glowplug engine of similar size. This is why the risk of hydraulic lock is always present if you flood the engine-and you will need to recognise it when/if it occurs, lest you damage the engine.

ChrisM

'ffkiwi'

#27

Forgot to ask ref your comment below. From the point of view of just freeing the engine and getting it to start, which is the best size prop from below?

"A 10x4 is a perfect match for peak revs-or if you had CL in mind a 9x6.....in the unlikely event you felt compelled to fly it in vintage team race-then an 8x8 might be appropriate. For vintage R/C perhaps a 10x5-but if you want to chug around gently it will have no trouble hanging on to an 11x4, 11x5 or even larger diameter for something like a lightly loaded slow flying vintage model. Its a big heavy motor, and produces just over 1/4 HP. "

"A 10x4 is a perfect match for peak revs-or if you had CL in mind a 9x6.....in the unlikely event you felt compelled to fly it in vintage team race-then an 8x8 might be appropriate. For vintage R/C perhaps a 10x5-but if you want to chug around gently it will have no trouble hanging on to an 11x4, 11x5 or even larger diameter for something like a lightly loaded slow flying vintage model. Its a big heavy motor, and produces just over 1/4 HP. "

#28

Join Date: Jul 2005

Location: Upper HuttWellington, NEW ZEALAND

Posts: 1,601

Likes: 0

Received 1 Like

on

1 Post

Forgot to ask ref your comment below. From the point of view of just freeing the engine and getting it to start, which is the best size prop from below?

"A 10x4 is a perfect match for peak revs-or if you had CL in mind a 9x6.....in the unlikely event you felt compelled to fly it in vintage team race-then an 8x8 might be appropriate. For vintage R/C perhaps a 10x5-but if you want to chug around gently it will have no trouble hanging on to an 11x4, 11x5 or even larger diameter for something like a lightly loaded slow flying vintage model. Its a big heavy motor, and produces just over 1/4 HP. "

"A 10x4 is a perfect match for peak revs-or if you had CL in mind a 9x6.....in the unlikely event you felt compelled to fly it in vintage team race-then an 8x8 might be appropriate. For vintage R/C perhaps a 10x5-but if you want to chug around gently it will have no trouble hanging on to an 11x4, 11x5 or even larger diameter for something like a lightly loaded slow flying vintage model. Its a big heavy motor, and produces just over 1/4 HP. "

ChrisM

'ffkiwi'

#30

Put it into an oven at 250F FOR 25 MINS. Took it out put a prop and it moves thru BDC OK but not TDC - seems to hit a stop at TDC, refuses to budge. Removed the compr. screw and tried - no difference. When trying TDC, it gives a slight pop sound as it leaves TDC suggesting a good fit and compression there!

#32

Join Date: Jul 2005

Location: Upper HuttWellington, NEW ZEALAND

Posts: 1,601

Likes: 0

Received 1 Like

on

1 Post

Moving the contra back up the cylinder can be achieved either by using compression to do the job-which is what happens in normal usage, or-in the case of a tight unit, by removing the cylinder setting it on a fiirm surface upside down and tapping the contra piston towards the top of the cylinder using a piece of down or a brass or alloy drift. In your case try the heating trick first-prop off, put it back in the oven again, with the compression screw backed off at least one full turn, let the engine get hot, , take it out, prop back on and see if you can turn it over top dead centre. Hopefull the contra will now move up in the bore till its movement is halted by the end of the compression screw. If the heating process does not achieve this, then you have no option but to take the cylinder off-by undoing the four screws at its base-and then proceed as I've suggested above. I hope I don't need to tell you to remove the compression screw before attempting to knock the contra piston up the bore? And only do one or two taps to move it. Then put everything back together and see if you can turn it over now. If you do have to go down the cylinder removal route, take the opportunity to clear out any gummed up oil from the underside of the contra piston with a cotton bud or tissue wad.

from your description it sounds as though ignorant fingers have played with the compression screw and wound it down so the contra is currently too far down inside the cylinder.

ChrisM

'ffkiwi'

#34

Join Date: Jul 2005

Location: Upper HuttWellington, NEW ZEALAND

Posts: 1,601

Likes: 0

Received 1 Like

on

1 Post

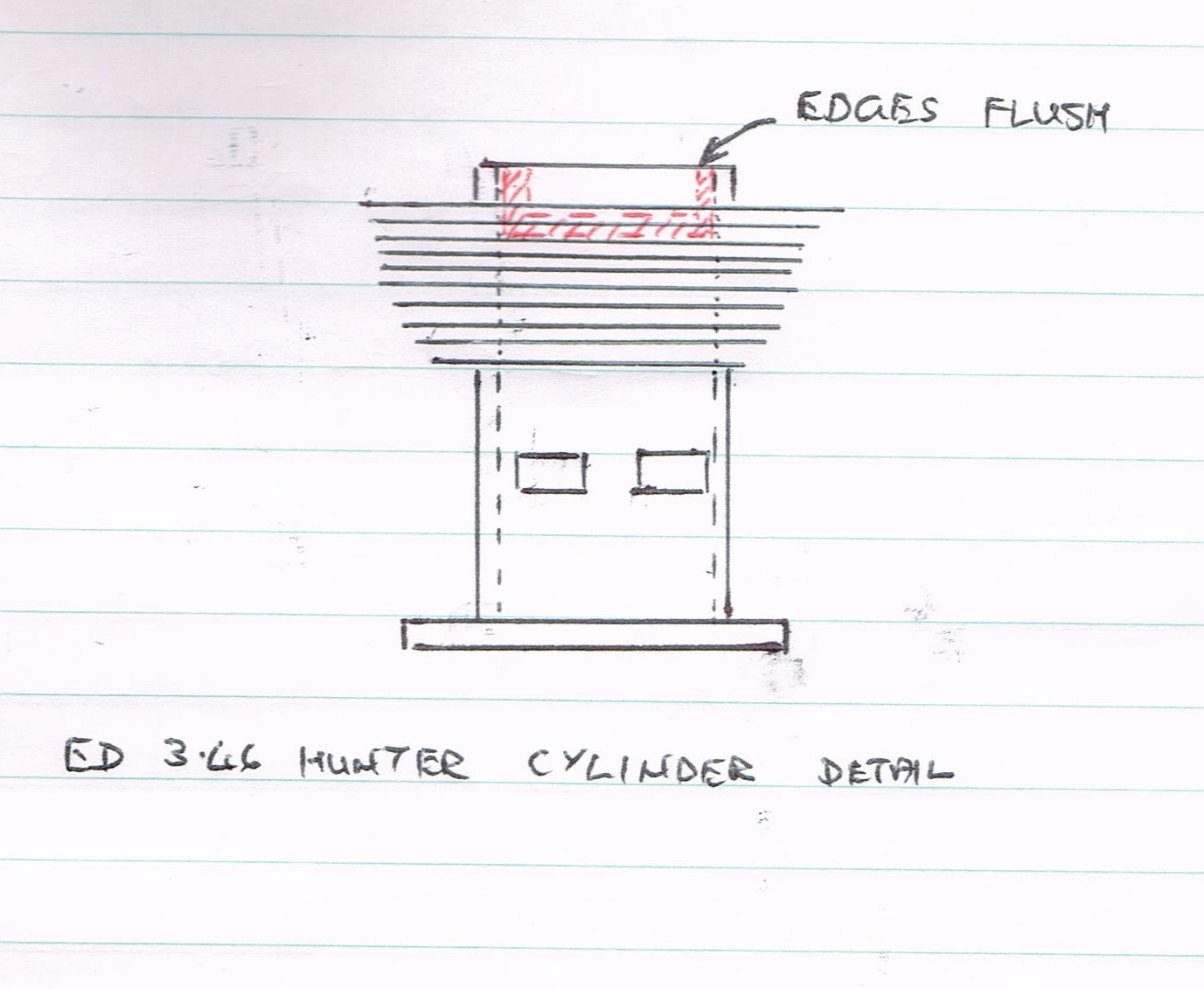

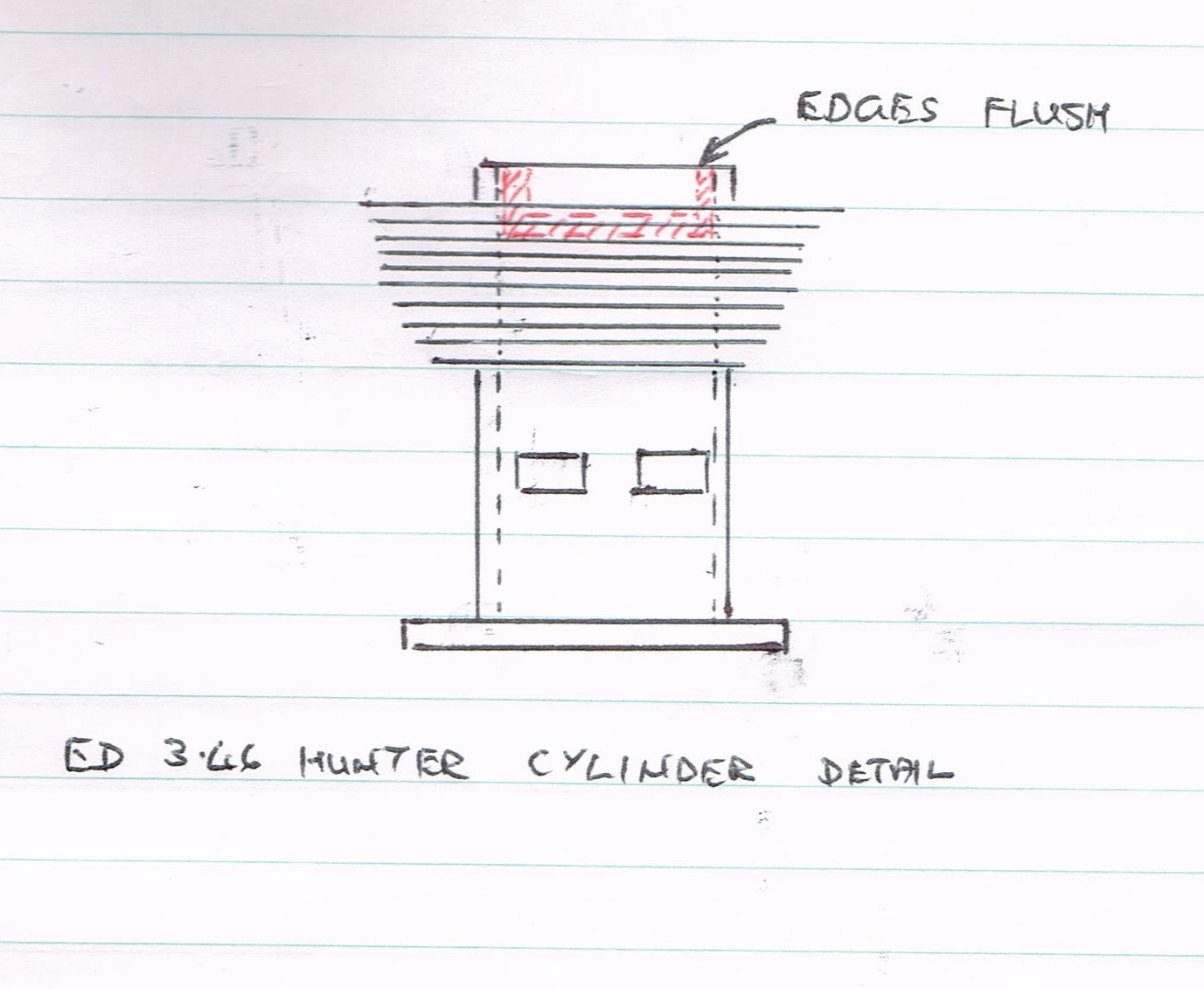

Well now that you have the cylinder off, I'd give it a thorough clean. Rusting seems odd-unless its a marine one and has been dunked....old castor residue looks a lot like rust to the uninitiated. checking on two of my display Hunters, that I know with absolute certainty are at their last running settings-the contra piston edges-that is the top of the portion in contact with the inner cylinder walls-are flush with the top of the cylinder.-so if the contra piston is further down inside the cylinder bore in your example you will need to knock it back to this approximate position. Try heat as before=just the cylinder-and then place upside down on a hard surface-a wooden cutting board or the anvil portion of a vice-and do the tapping with a hammer. I'd use something solid-like round bar, rather than tubing to drift with the hammer....and a reasonably close fit in the cylinder-say 15mm diameter...at a pinch even a piece of wooden dowel 3 or 4 inches long.

If no joy using this approach then it looks like an extended soak with a penetrating oil will be required..... See the sketch below-the contra piston cross section is shown in red-in the running position it occupies in the two examples of my own that I checked. If you can get yours to this position then you should be in the correct ball park for successful running..

ChrisM

If no joy using this approach then it looks like an extended soak with a penetrating oil will be required..... See the sketch below-the contra piston cross section is shown in red-in the running position it occupies in the two examples of my own that I checked. If you can get yours to this position then you should be in the correct ball park for successful running..

ChrisM

Last edited by ffkiwi; 05-09-2022 at 05:11 PM.

#38

Join Date: Jul 2005

Location: Upper HuttWellington, NEW ZEALAND

Posts: 1,601

Likes: 0

Received 1 Like

on

1 Post

You were advised more than 6 weeks ago not to use nail polish remover-it is basically just acetone-which isn't a good solvent. What were you trying to achieve by posting a blurred out-of-focus photograph of the engine' cylinder head? It tells us nothing-and you're not going to achieve anything towards solving the problem until you remove the head and work on shifting the contra piston location.

ffkiwi

ffkiwi

#39

Sorry about the pic. I will now try using marvel oil which hopefully can free it. Actulally, I also tried paint thinner, no luck. Now, I will remove the 6 screws on the top of cylinnder head and give it another try.

#40

Join Date: Jul 2005

Location: Upper HuttWellington, NEW ZEALAND

Posts: 1,601

Likes: 0

Received 1 Like

on

1 Post

ChrisM

'ffkiwi'

Last edited by ffkiwi; 06-15-2022 at 05:07 PM.

#42

I’ve always had great success using acetone to free up a stuck engine run on castor laden fuel. Much better than using methanol or mixed glow fuel. I usually heat the engine up a little first to get the carb and crank moving a little bit, then add solvent and keep moving things. After 5-10 minutes, dump it out, rinse, and add oil. I use ATF mixed 10:1 with Seafoam - works a great for keeping carbon deposits at bay when used as after-run/storage oil.

Also; the very best penetrating oil I’ve used is a mixture of Acetone and ATF mixed 50/50. I keep it stored in a metal can with a tightly fitted cap to keep the acetone in - much like model diesel fuel.

just my 2¢.

Also; the very best penetrating oil I’ve used is a mixture of Acetone and ATF mixed 50/50. I keep it stored in a metal can with a tightly fitted cap to keep the acetone in - much like model diesel fuel.

just my 2¢.

#46

#48

#49

#50

The following users liked this post:

Dieseltinus (07-01-2022)