Welcome to Club SAITO !

Senior Member

Yes sir, I have the engine mounts here but mounting F1 is the last step for some reason, the 125 is anxious to get on there. I am going to power the CHI with a 7.4 volt battery and the receiver with a 6.6 volt LIFE battery. What does coreless mean? The servos are all JR E 355 except the throttle.

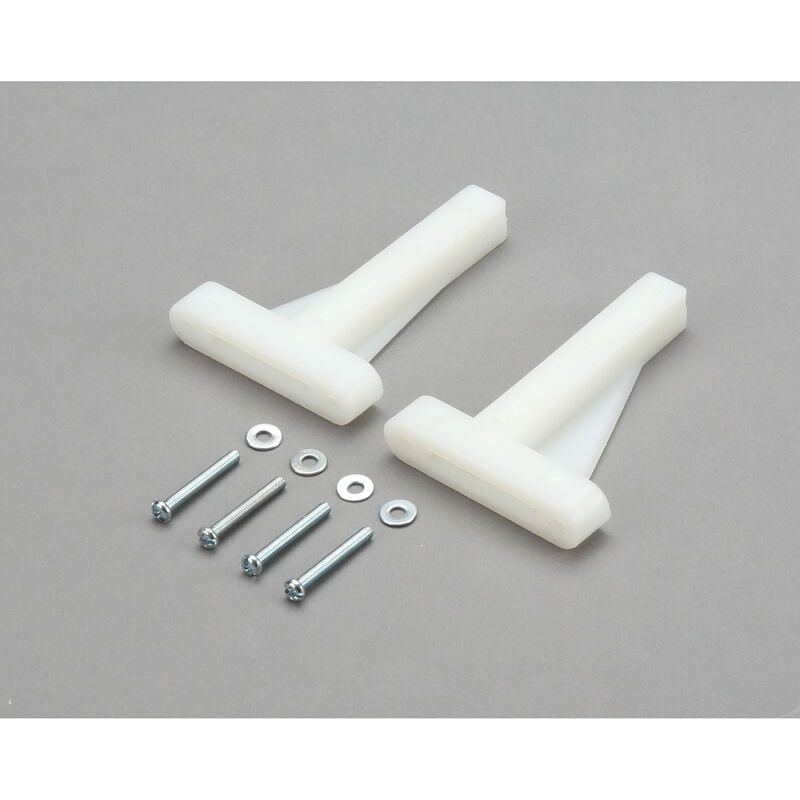

I have these Hangar 9 mounts in 120 size.

6.6V servo, good with Li-Fe battery set up [Control Signal Type] PWM Only [Stall Torque] 3.0 kgf-cm (6.6V) / 41.7 oz-in (6.6V) [Speed] 0.1 Sec/60° (6.6V) [Weight] 25 g / 0.88 oz [diemension] 35 x 15 x 30 mm / 1.38 x 0.59x 1.18 in [Length of lead harness] 250mm [Operating Voltage] 4.8V - 7.0V (Li-Fe 6.6v recommended

This tiny little guy will be the throttle servo.

I have these Hangar 9 mounts in 120 size.

6.6V servo, good with Li-Fe battery set up [Control Signal Type] PWM Only [Stall Torque] 3.0 kgf-cm (6.6V) / 41.7 oz-in (6.6V) [Speed] 0.1 Sec/60° (6.6V) [Weight] 25 g / 0.88 oz [diemension] 35 x 15 x 30 mm / 1.38 x 0.59x 1.18 in [Length of lead harness] 250mm [Operating Voltage] 4.8V - 7.0V (Li-Fe 6.6v recommended

This tiny little guy will be the throttle servo.

Last edited by 1200SportsterRider; 03-26-2023 at 03:00 AM. Reason: Add image

Senior Member

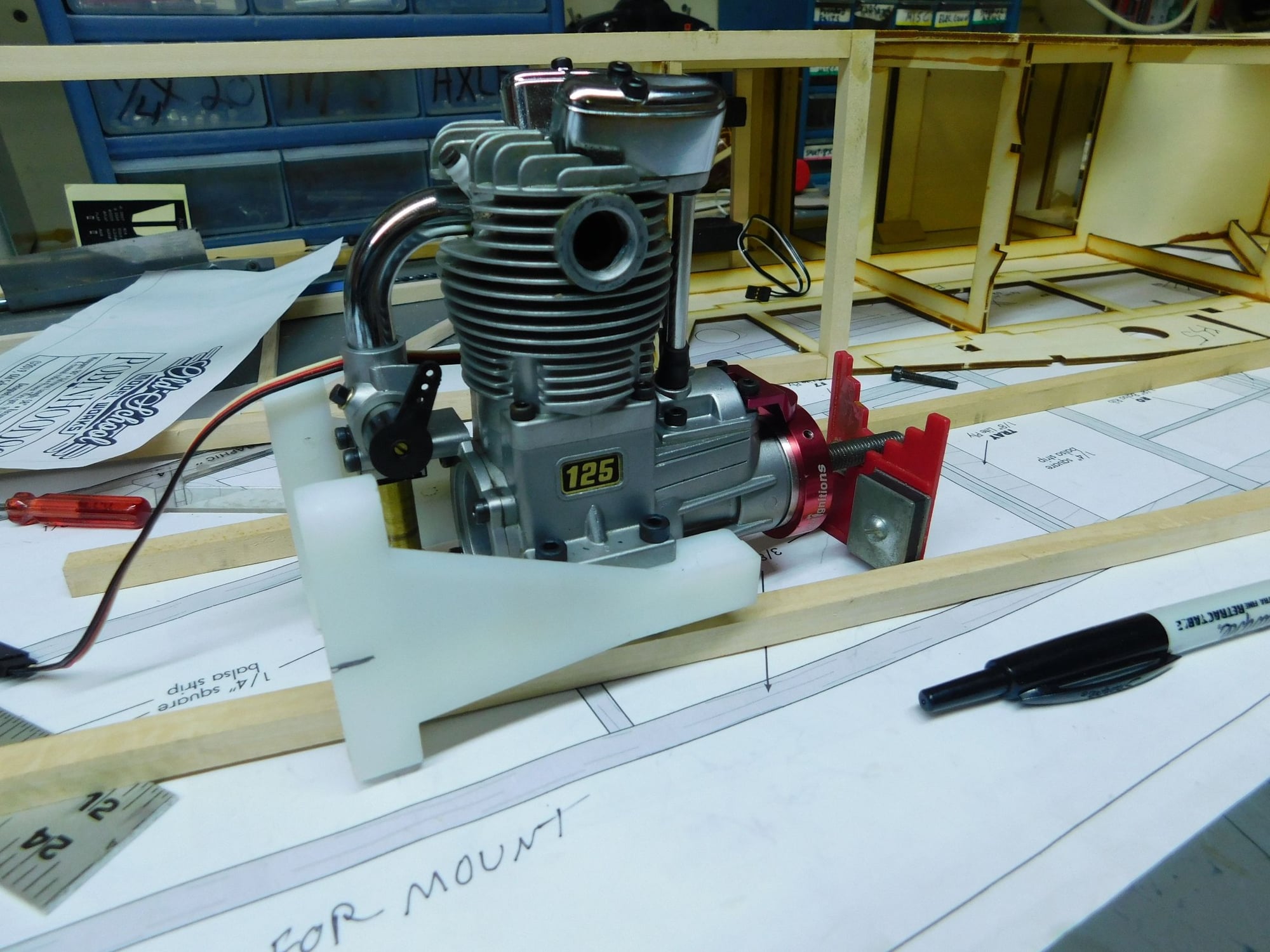

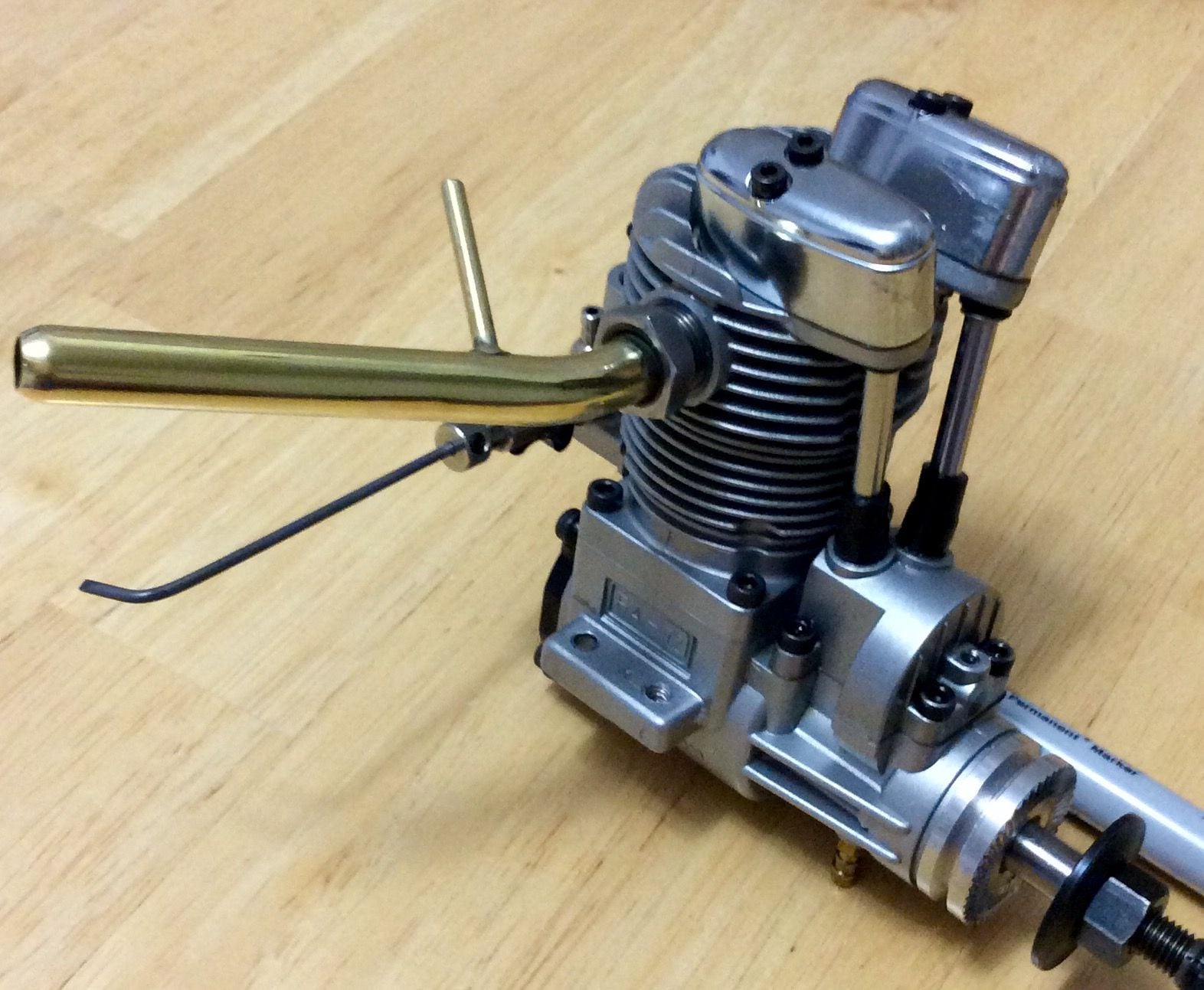

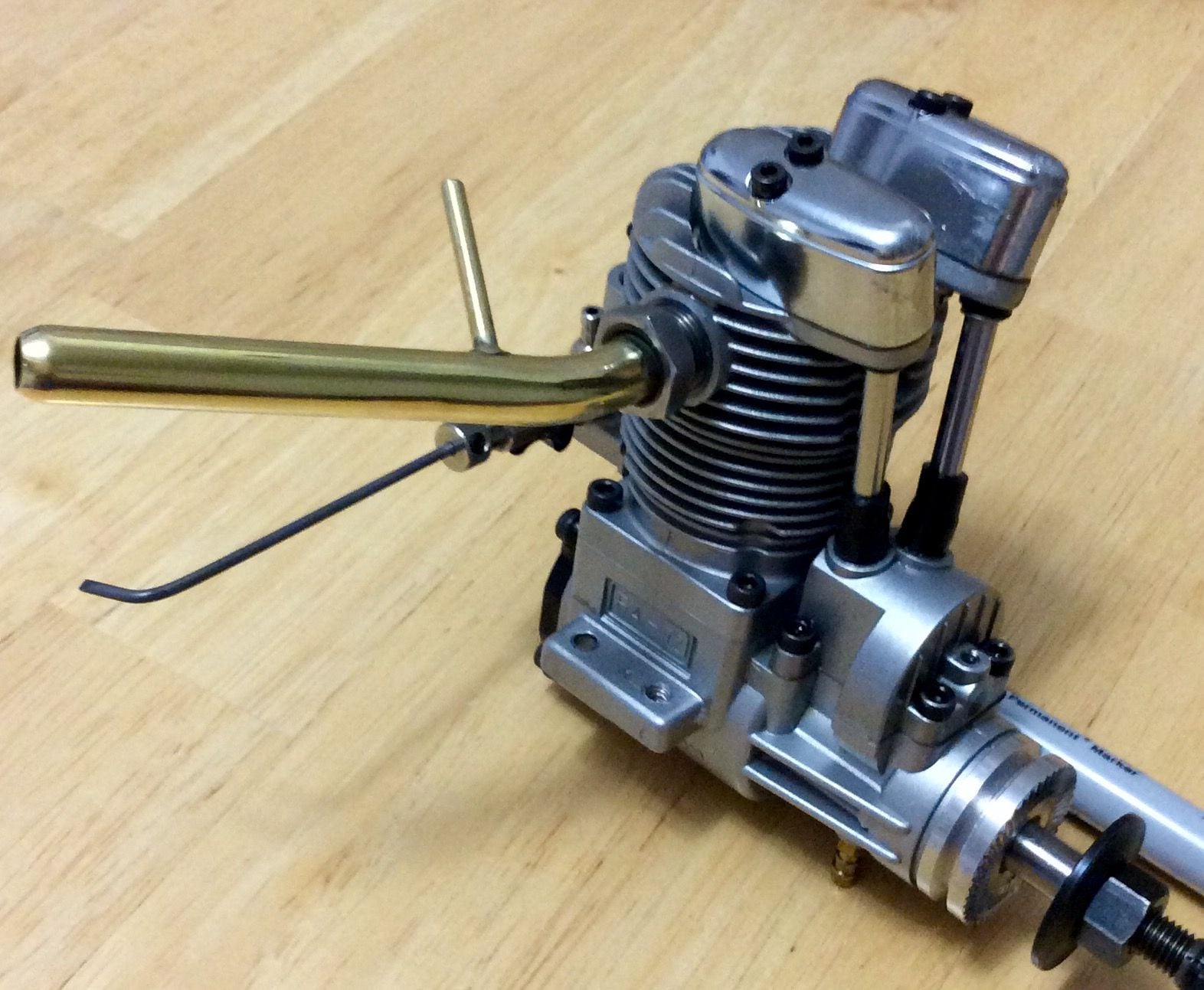

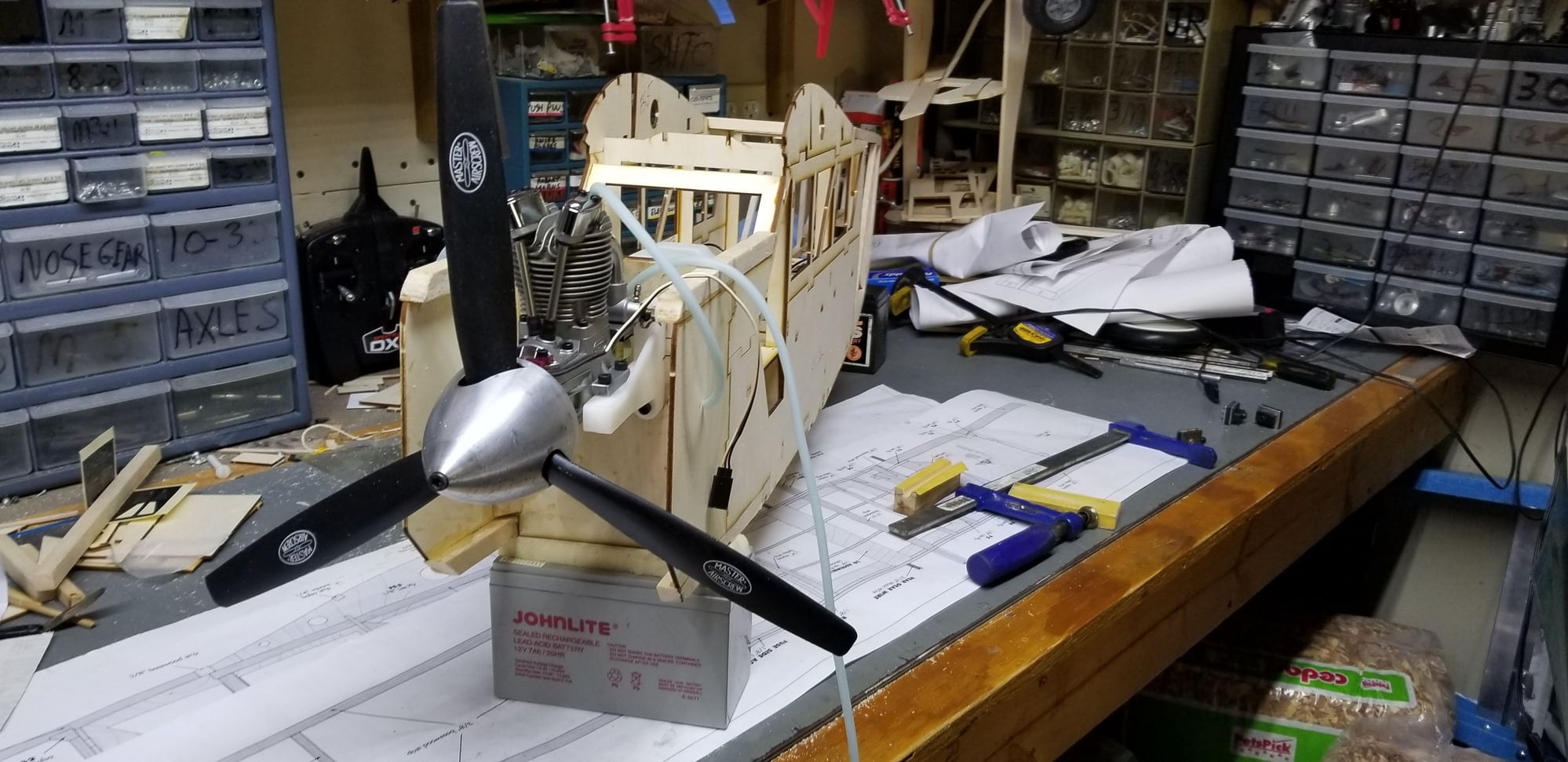

The 125-A is mounted on the mounts and F-1 drilled for them, I'll drill F-2 and F-3 through F-1. I don't have any M4 x 35 mm bolts to bolt it to the firewall, I will hit Micro Fasteners up for them in a couple of minutes. I'm still having fun with it.

Da pitcher loader ain't werkin ryte now.

This 150 sure needs a cylinder.

Da pitcher loader ain't werkin ryte now.

This 150 sure needs a cylinder.

Last edited by 1200SportsterRider; 03-28-2023 at 06:05 AM. Reason: Add picture

My Feedback: (11)

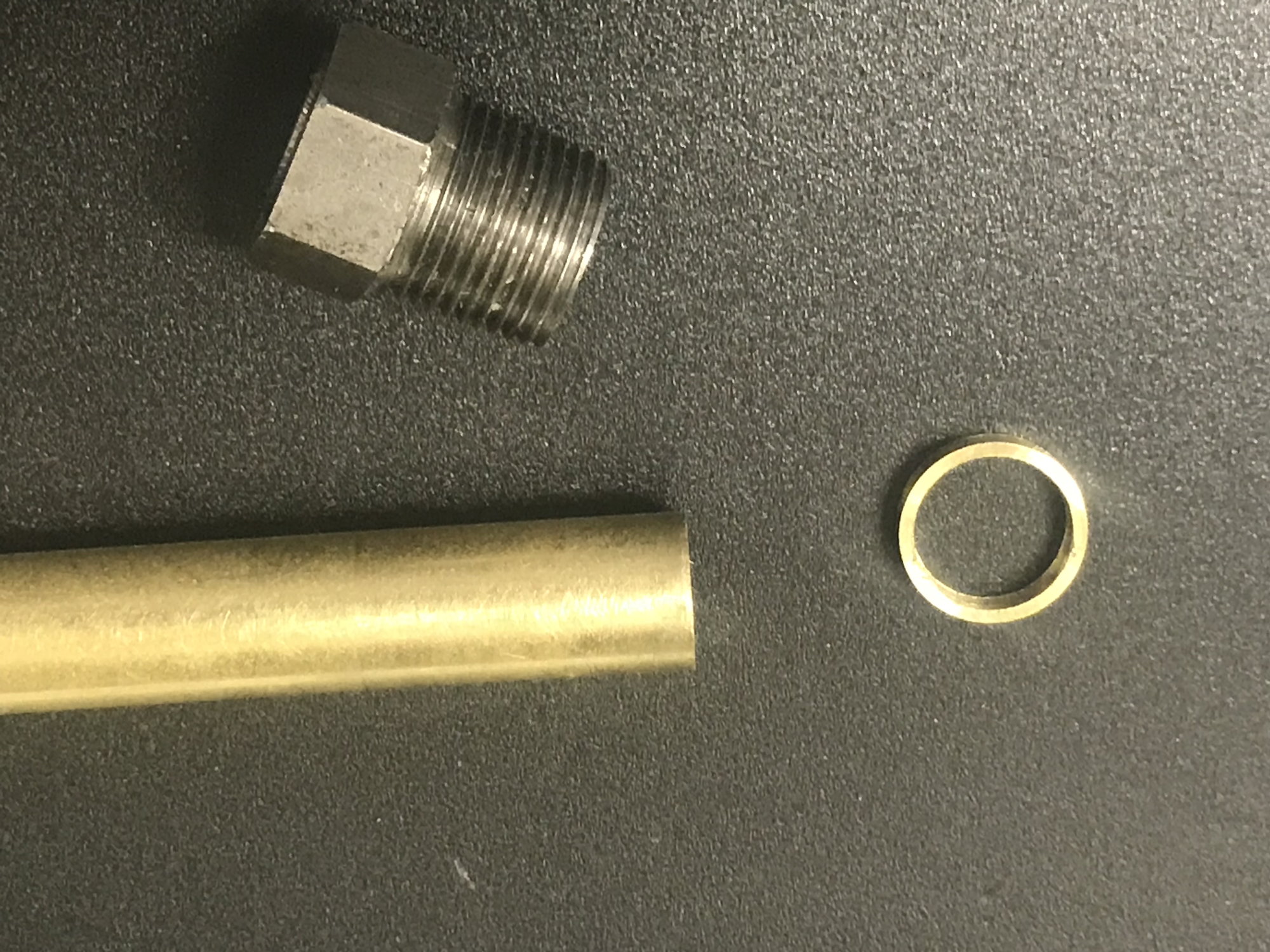

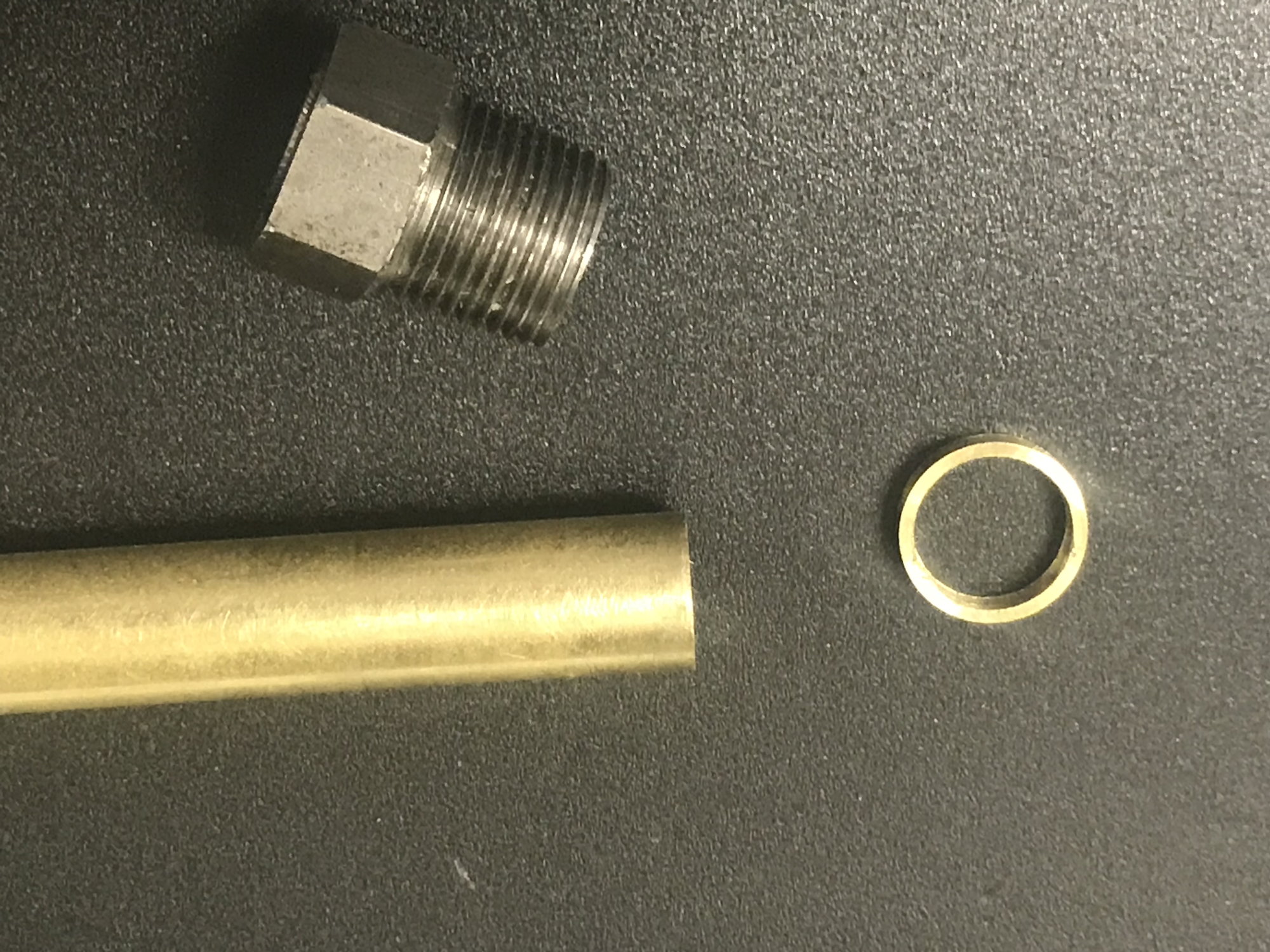

Looking for flexible mufflers. The nut size is 10mm .

just bot a plane thats been hanging from the ceiling of lhs. Has the engine but missing mufflers. The engine was never run

just bot a plane thats been hanging from the ceiling of lhs. Has the engine but missing mufflers. The engine was never run

Senior Member

Flared copper is not likely to survive well.

A machined ring, hard silver-soldered (brazed) in place, and the proper gland-nut setup similar to the factory setup

works well.

A machined ring, hard silver-soldered (brazed) in place, and the proper gland-nut setup similar to the factory setup

works well.

My Feedback: (1)

hey guys. I sure we all are a bit alike. meaning we all don't have every type of grease made just setting on our shelfs in our shops.

well. I replace the sliding-gibs on my Sherline Mill. I don't want to do that again LOL. Sherline recommends oil to oil the gibs and the metal to metal dovetails on the opposite side of the table. I tried that but knew the oil would drip. and it did. I didn't have a thin grease. but I'm smarter than the average bear. well. so I didn't have to buy some $$$ grease that I knew would be setting around for 15 years or loger I thought I would try something. I took Kendal's SHP auto grease (that I have had setting around for 17 years unopen) and mixed in drop by drop by drop Quaker 80-90 gear Lube. and it mixed up very well and thinned out the grease and as I waited for parts to come I let it set a week and it didn't separate. and it seems to be working slick. yee-up, "slick's" the word.

now I have to find a reason to use the Mill.

later.

Jim

well. I replace the sliding-gibs on my Sherline Mill. I don't want to do that again LOL. Sherline recommends oil to oil the gibs and the metal to metal dovetails on the opposite side of the table. I tried that but knew the oil would drip. and it did. I didn't have a thin grease. but I'm smarter than the average bear. well. so I didn't have to buy some $$$ grease that I knew would be setting around for 15 years or loger I thought I would try something. I took Kendal's SHP auto grease (that I have had setting around for 17 years unopen) and mixed in drop by drop by drop Quaker 80-90 gear Lube. and it mixed up very well and thinned out the grease and as I waited for parts to come I let it set a week and it didn't separate. and it seems to be working slick. yee-up, "slick's" the word.

now I have to find a reason to use the Mill.

later.

Jim

Senior Member

(quote) hey guys. I sure we all are a bit alike. meaning we all don't have every type of grease made just setting on our shelfs in our shops."

Now Jim, I don't know if I'd go that far. Slick is good though, good job. This is one of my fave's for a long time.

Slick is good though, good job. This is one of my fave's for a long time.

Now Jim, I don't know if I'd go that far.

Slick is good though, good job. This is one of my fave's for a long time.

Slick is good though, good job. This is one of my fave's for a long time.

Last edited by 1200SportsterRider; 03-29-2023 at 01:58 AM. Reason: Add image

Senior Member

My Feedback: (3)

Jim, I was a Millwright for over 20 years and all the Bridgeports had a manual pump lube system we loaded with Way 68. All our other CNC mills with ways and Gibbs, as well as anything with linear bearings basically used the same setup.Those had an internal pump cycle timed through the controller. Only issue is if stagnant for any length of time the Waylube tends to have the wax component settle out.

Otherwise, if you want a long lasting and tenacious grease I would recommend a graphite lube. Just avoid touching any as it is a bit messy. There are also high-pressure greases that have some serious surfactant qualities, meaning they'll stay where applied and not squeeze out under load.

Don't use anything like Anti-Seize.

ps. I have worked with Waylube as thick as 220. That has the flow characteristics of epoxy!.

Otherwise, if you want a long lasting and tenacious grease I would recommend a graphite lube. Just avoid touching any as it is a bit messy. There are also high-pressure greases that have some serious surfactant qualities, meaning they'll stay where applied and not squeeze out under load.

Don't use anything like Anti-Seize.

ps. I have worked with Waylube as thick as 220. That has the flow characteristics of epoxy!.

Last edited by Cougar429; 03-29-2023 at 05:55 AM.

Join Date: Jan 2004

Location: lake in the Hills,

IL

Posts: 977

Likes: 0

Received 14 Likes

on

14 Posts

Jim

Great job, you are done.

I have an old south bend lathe that they say should be maintained with 3 different lubes. I use what ever is handy at the time. Still going strong, 80 years old ( the lathe that is).

Great job, you are done.

I have an old south bend lathe that they say should be maintained with 3 different lubes. I use what ever is handy at the time. Still going strong, 80 years old ( the lathe that is).

My Feedback: (1)

Jim

My Feedback: (1)

Jim, I was a Millwright for over 20 years and all the Bridgeports had a manual pump lube system we loaded with Way 68. All our other CNC mills with ways and Gibbs, as well as anything with linear bearings basically used the same setup.Those had an internal pump cycle timed through the controller. Only issue is if stagnant for any length of time the Waylube tends to have the wax component settle out.

Otherwise, if you want a long lasting and tenacious grease I would recommend a graphite lube. Just avoid touching any as it is a bit messy. There are also high-pressure greases that have some serious surfactant qualities, meaning they'll stay where applied and not squeeze out under load.

Don't use anything like Anti-Seize.

ps. I have worked with Waylube as thick as 220. That has the flow characteristics of epoxy!.

Otherwise, if you want a long lasting and tenacious grease I would recommend a graphite lube. Just avoid touching any as it is a bit messy. There are also high-pressure greases that have some serious surfactant qualities, meaning they'll stay where applied and not squeeze out under load.

Don't use anything like Anti-Seize.

ps. I have worked with Waylube as thick as 220. That has the flow characteristics of epoxy!.

Jim

My Feedback: (1)

I found a nice and clean Bridgeport Mill, you know, it's some 7ft tall. and it had the CNC added. all for $2,700. but I have no place for it and I don't know that much about machining. and I don't have all the other goodies I would need.

Jim

Senior Member

I have this Micro Mark Lathe, it's the smaller of the two they make. I use Corrosion X on the, "rails", is that what you're calling the "ways". Everything that turns is ball bearings.

Senior Member

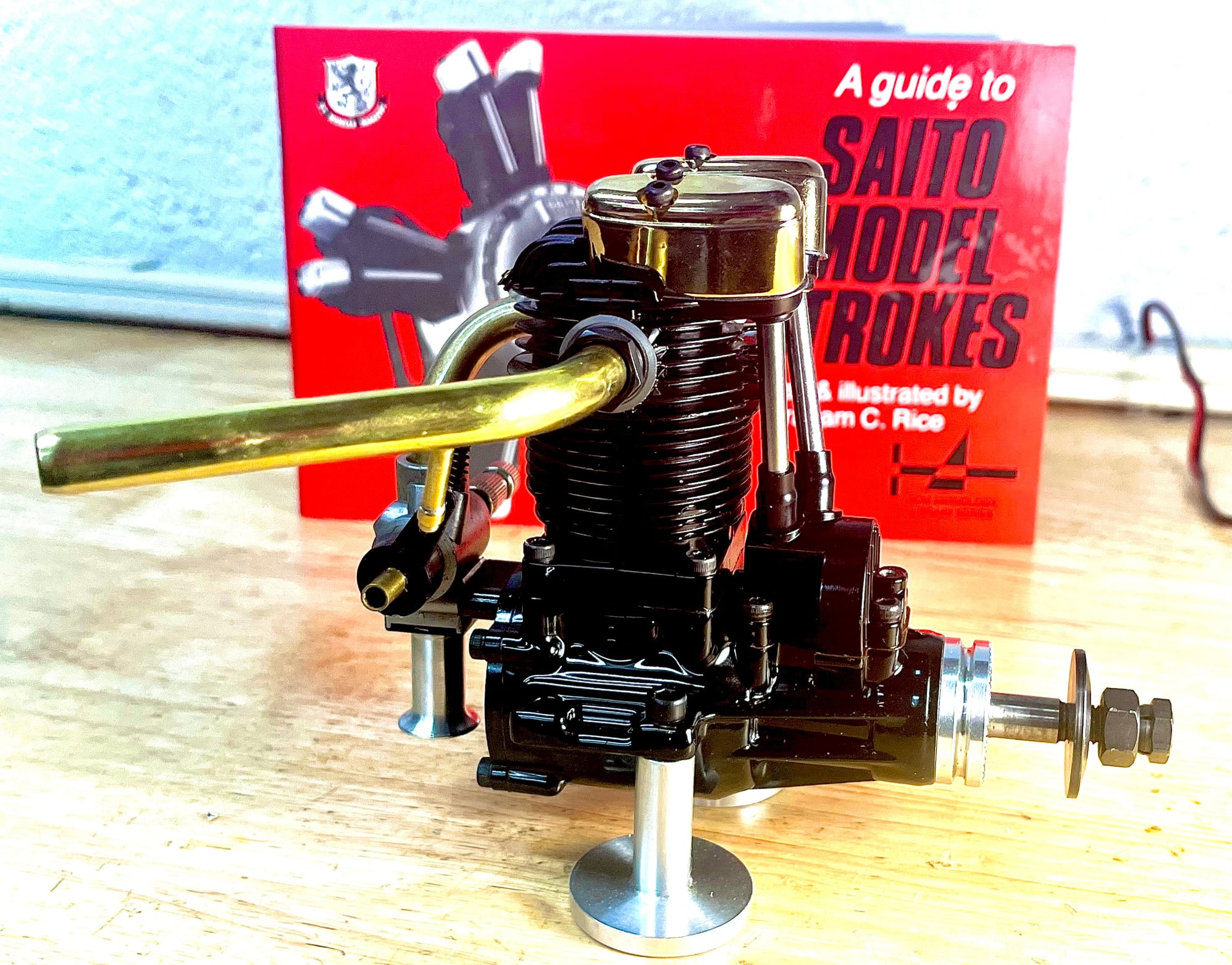

The prime mover is fitted and temporarily mounted, a 16 OZ Roto Flow tank is in place, lots of finishing touches now, there will be plenty of room beside the tank for the CHI and it's battery.

My Feedback: (1)

I thought you bought a Sherline. you see a lot of those Micro Mark lathes on YouTube. they cut really nice.

Jim

Senior Member

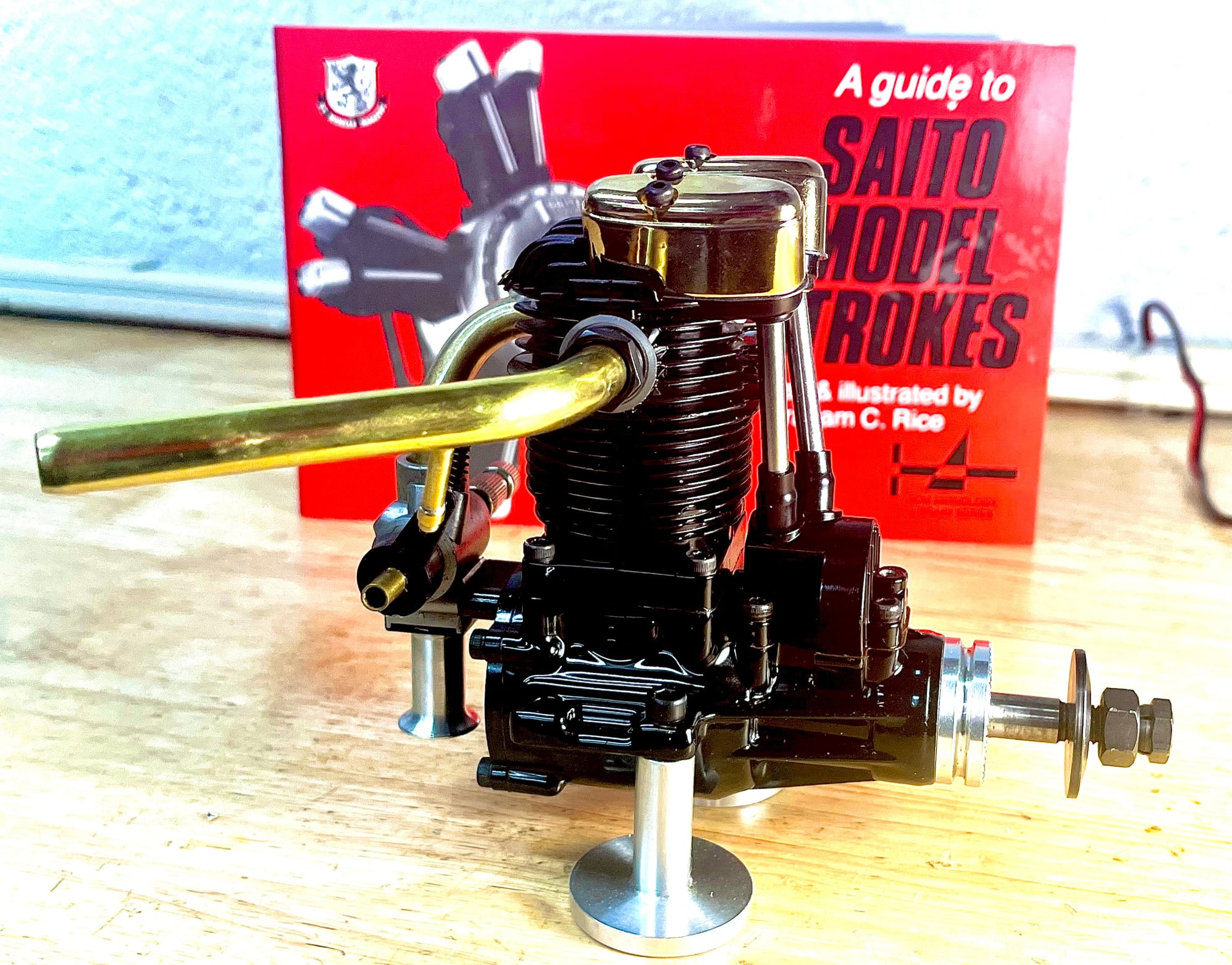

I fired up the little lathe pictured above and made an offset adapter for Saito 125 so I wouldn't have to run the throttle cable over top of the fuel tank. I still need to drill and tap for the inboard grub screw. Both ends are a snug slip onto the carb barrel and into the throttle arm.

Last edited by 1200SportsterRider; 04-02-2023 at 03:04 PM. Reason: Add comment